This

page outlines use of common hand tools located in the toolbox at each lab

workstation.

Each

workstation toolbox contains the following items:

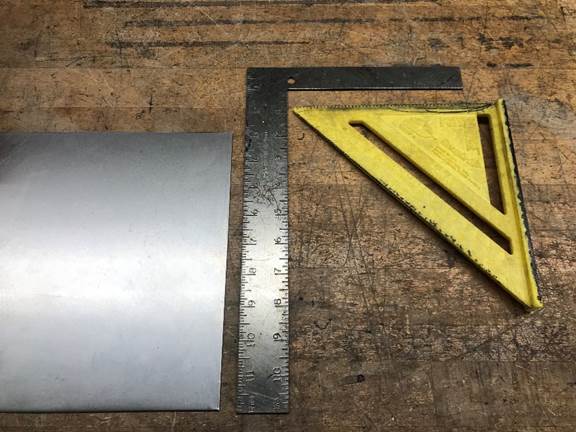

Upper Compartment

1. 90° carpenter square

2. 90° speed square

3. 10′ tape measures

4. Sharpie permanent markers

5. scissors

Top Drawer

1. pliers

2. screwdrivers (2 phillips,

2 slotted)

Middle Drawer

1. ball-end Allen wrench set

2. ball-end 5/32” Allen wrench

3. ball-end Allen drivers

4. flat-end Allen drivers

5. tee-handle Allen driver

6. hand files

7. metric / standard fastener gauge

Bottom Drawer

1. metric / standard wrench set

The

top portion of each toolbox contains measurement and layout tools, including

Sharpie® markers, tape measures, a ruler, a speed square, a

carpenter’s square, and a pair of scissors.

Each

tape measure has units in inches, where each tick mark denotes 1/16″

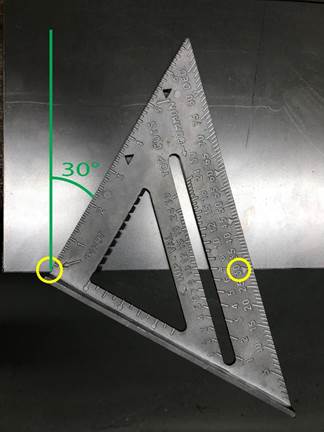

The

speed square and carpenter’s square are commonly used

for sheet metal layout. Both tools can

be used for creating right angles.

The

speed square can be

used to mark an array of common angles by pivoting the square around the 90°

corner and lining up the edge of the work piece with the desired angle noted on

the hypotenuse as shown in the example for a 30° angle.

The top drawer of the toolbox contains

short and medium length Phillips-head and flat-blade screwdrivers, needle nose

pliers, and linesman pliers.

Linesman pliers can be used for

cutting and bending thin rod or wire. Never cut motor wires without express

permission from a TA, and never cut wires which are connected to a power

source.

Needle nose pliers can be used for

bending thin rod or wire, or for holding onto small parts. Never

bend motor wires, as this can cause them to break over time and they cannot be

replaced.

Common

fastener head types used in the lab are (from left to right) Phillips-head,

flat-head, external hex, and internal hex.

Allen wrenches and combination wrenches for the latter two head types

can be found in the second and third toolbox drawers respectively.

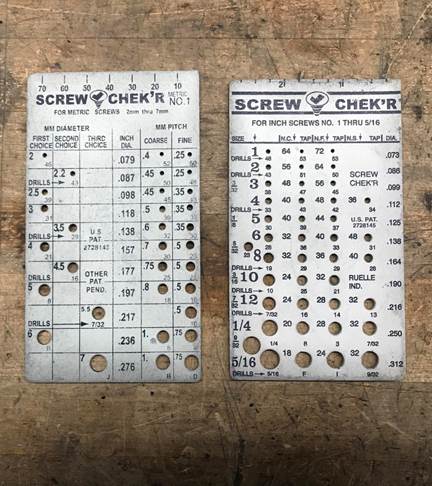

The

second drawer of the toolbox contains two yellow handled, ball ended 5/32″

hex wrenches; two red handled, square ended 5/32″

hex wrenches; a set of standard hex wrenches in 1/32″

increments; a yellow tee-handled Allen wrench; a standard and metric thread

checker; and two files.

Each

toolbox contains three types of the 5/32″ hex

wrenches most commonly used on the ¼-20 button head cap screws used to attach

80-20 components.

The

yellow 3/32″ tee-handled Allen wrench is the

appropriate size for the 10-24 set screws commonly used on robot wheel hubs.

Fastener

gages can be used to determine the thread pitch of standard and metric machine

screws. Gently thread the fastener into

the gauge. The fastener should thread

easily into the properly sized hole by hand.

If additional force is required, the wrong gage location is likely being

used, and a different pitch should be checked.

The

circular file can be used for deburring holes and internal features, while the

flat file is better suited for flat or external features. The file should be held at a 45° angle to the

part, and run from tip to handle across the length of the edge. Do not use the file in the reverse direction,

as doing so will damage the file.

The

third drawer of the toolbox contains a set of metric and SAE combination

wrenches.

A

combination wrench or a socket wrench should be used anytime a hex head

fastener or nut needs to be tightened.

The appropriately sized wrench will slide over the hex easily, but will

not have more than 5° of wasted motion.

Using a wrench which is too large will result in damage to both the

fastener and the tool.

IMPORTANT NOTE ABOUT

FASTENERS: When

installing fasteners, always stop and make sure the fastener

threads together all the way in by hand before using a wrench to tighten it. If the fastener threads are the correct match

and in good condition, a tool should never be needed to thread the fastener

together, only to tighten it. In

addition, always make sure each fastener has at least 5 threads of engagement

before tightening, or the threads will be destroyed when the fastener is

tightened.