WHAT THE WHAT???

Quick Links

(Table of Contents)

Introduction

/ Purpose of Archive [RETURN TO

T.O.C.]

For a change of pace, this section contains a collection of photos

demonstrating poor techniques, tooling, safety protocols, and the like. See if you can identify the issue(s) in each

photo before reading the captions. Please submit ideas for additional points here.

Drill Presses

[RETURN TO T.O.C.]

1.

Operator does not have the vise pressed against the drill press

column or clamped to the table. (That

particular vise does have a vee jaw for clamping cylindrical

workpieces, so that’s okay.)

2.

Operator is wearing gloves and does not have the part anywhere

close to securely clamped.

3.

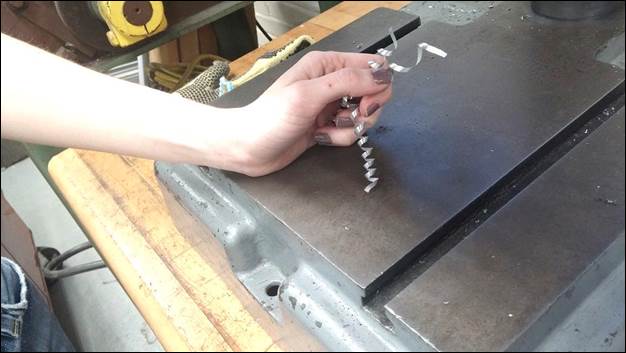

Operator is touching chips with her bare hand(s).

4.

Operator is wearing gloves and long sleeves, but makes up for it

by not wearing eye protection.

5.

Gotcha! Operator

is safely operating the drill press using the following safety protocols:

a.

the operator is wearing safety glasses

b.

the operator has her hair tied up

c.

the operator is not wearing any loose clothing

d.

the operator is not wearing any jewelry on her hands

e.

the operator has the part securely clamped

f.

the operator has the drill bit aligned with the center hole in the

table

Milling Machines [RETURN TO T.O.C.]

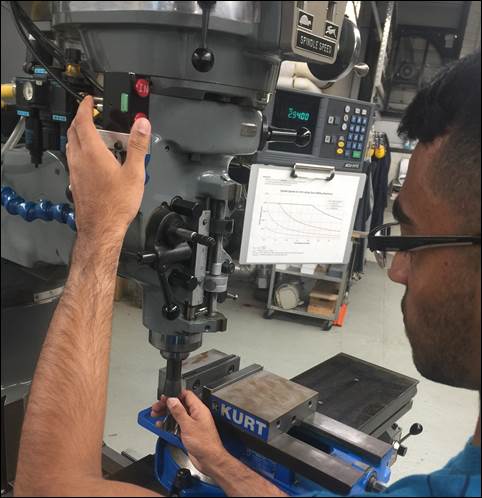

1.

Operator is attempting to improperly

perform a tool change (quill is not raised or locked, tool is not completely over the

plastic table covers, collet is not correctly inserted into the spindle, not

using a rag to protect his hand, pressing the wrong button).

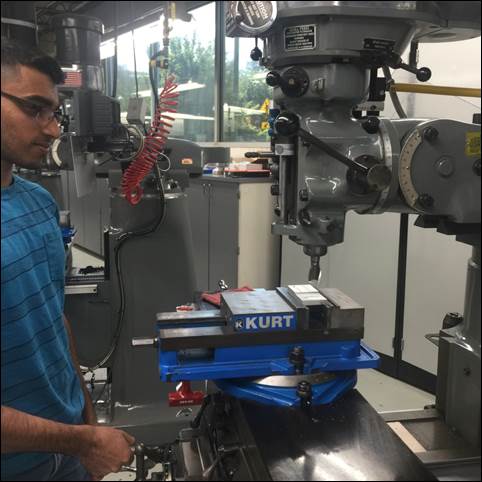

2.

Operator is performing cutting

operations before removing parallels from the vise. Mill is also in LO range.

3.

Operator is using the power

feed without their hand on the joystick.

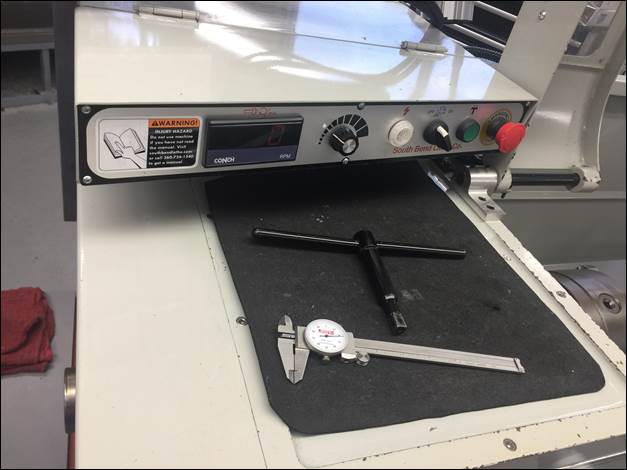

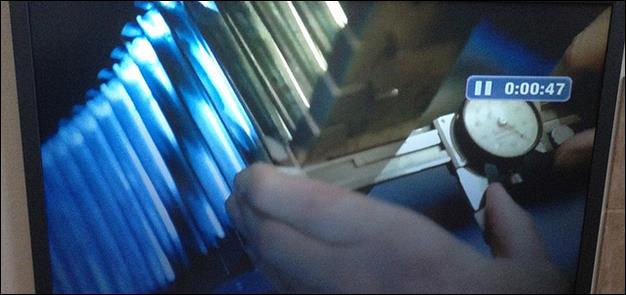

4.

Operator did not return

calipers to their storage box.

Lathes

[RETURN TO T.O.C.]

1.

Operator left chuck key in chuck.

2.

Operator did not check HI / LO range before turning on lathe (it

is incorrectly set to LO range when facing/turning).

3.

Operator is reaching across/over the lathe chuck with their right

hand.

4.

Operator is rotating the

chuck/work backwards.

5.

Operator is operating power

feed without their hand on it.

6.

Operator is drilling without

the tailstock locked.

7.

Operator did not return

calipers to their storage box.

Fasteners

[RETURN TO T.O.C.]

1.

Some genius thought slotted screws would be a good idea. Come on, that’s always funny :).

2.

Another genius thought it would be a good idea to place fastener

threads in shear. Unfortunately, these

were on flywheels on commercial aircraft engines. The solution was (surprise!) a redesign that

used dowel pins to react the shear forces, which allowed the fasteners to do what

they do best: clamp. Click the

image for the full service bulletin report.

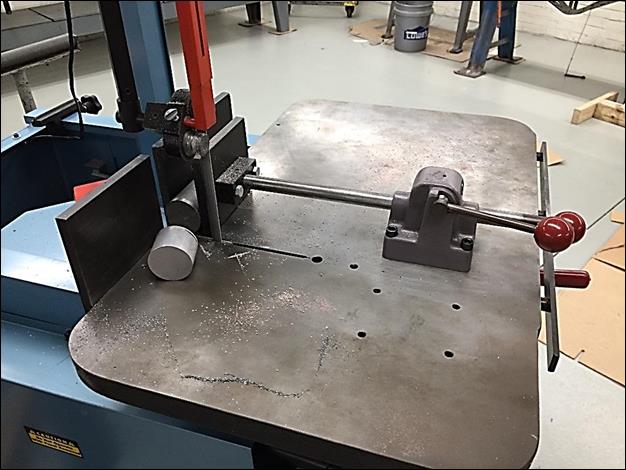

1.

Operator allowed read edge of blade to completely pass workpiece.

2.

Operator improperly clamped workpiece so the blade is presented

with a non-uniform C.S.A. as the cut is made.

3.

Operator does not have her long hair tied back and is wearing long

sleeves.

4.

Operator does not have a hand on the power feed.

5.

Gotcha! Operator

is safely operating the Roll-In using the following safety protocols:

a.

the operator

is wearing eye protection

b.

the part is

clamped properly (engaging the largest number of teeth)

c.

the operator

is not wearing loose clothing

d.

the operator

is not wearing loose jewelry

e.

the

operator’s hair is tied up / back

6.

Operator is not wearing safety glasses and is wearing a bracelet.

7.

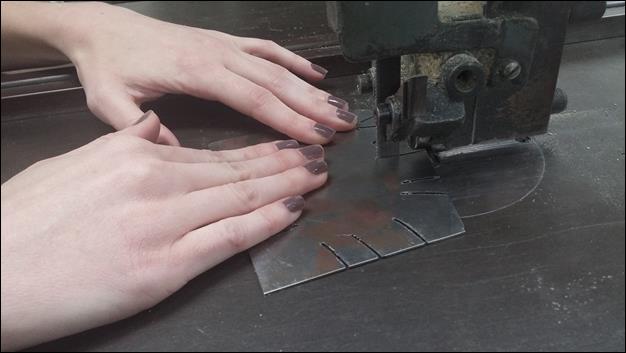

Operator has her hand in the plane of the blade.

8.

Operator is wearing gloves.

9.

Gotcha. Operator

is safely operating the Do-All using the following safety protocols:

a.

the operator

is wearing safety glasses

b.

the operator

has her hair tied up

c.

the operator

is not wearing any loose clothing

d.

the operator

is not wearing any jewelry on her hands

e.

the

operator’s hand is not in the plane of the blade

Welding Shop [RETURN TO

T.O.C.]

1.

Operator is not wearing a welding helmet, welding jacket, or

welding gloves.

2.

Operator should never weld in close proximity to flammable chemicals/liquids

(like the acetone in the red-top bottle).

3.

Gotcha. Operator

is safely operating the welder using the following safety protocols:

a.

safety glasses

b.

welding mask

c.

welding jacket

d.

welding gloves

Sheetmetal Equipment [RETURN TO

T.O.C.]

1.

Operating a shear with two

people and failing to wear safety glasses.

2.

Not wearing gloves when

using non-powered sheetmetal equipment.

3.

Attempting to drill sheetmetal while holding it by hand and

wearing gloves when operating powered equipment.

4.

Using vise grips instead of

c-clamps to secure sheetmetal to the table for grinding.

5.

Mixing up order of

operation on sheetmetal equipment (punch holes, then

bend!).

Project Motors and Related [RETURN TO T.O.C.]

Control Boxes and

Electrical [RETURN TO T.O.C.]

Metrology

[RETURN TO T.O.C.]

1.

Operator is a little confused about proper caliper use :).

Miscellaneous

[RETURN TO T.O.C.]

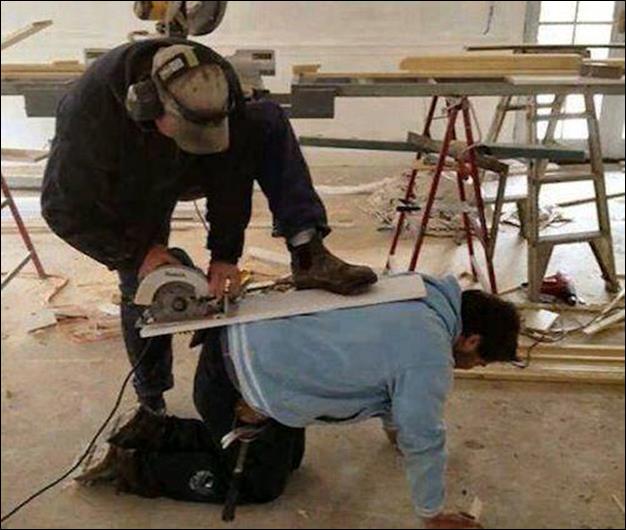

1.

If you are going to do it, own it …

2.

Sometimes you just need a little more …

3.

Teamwork.

4.

New lightweight welding masks just hit the market …

5.

Barney’s boss told him he didn’t need a taller ladder…